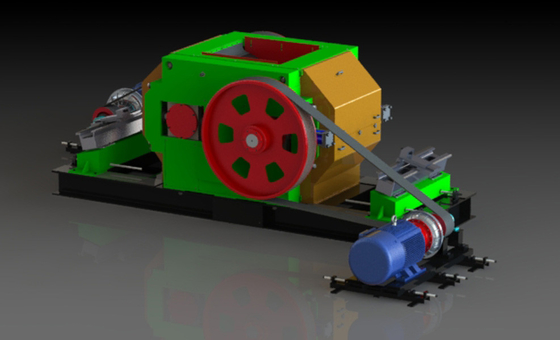

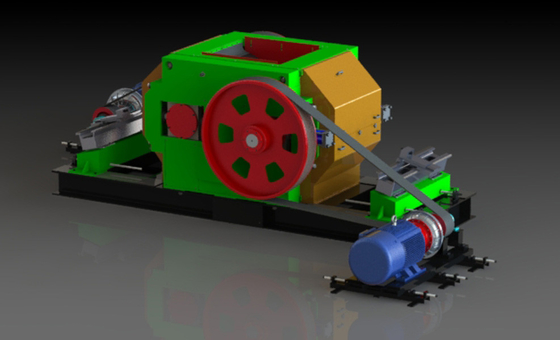

High Speed Fine Roller Crusher With Double Rollers For Hard Raw Material Preparation

1. Introduction for high speed fine roller crusher with double rollers for hard raw material preparation

The refine roller crusher is one of the main equipment in the raw material processing section of clay brick making, and it is suitable for fine treatment of wet and soft raw materials.

The grain size composition is obtained by crushing, thus to improve the plasticity of the brick material. Which is suitable for brick material with relative moisture content not higher than 25%.

The appropriate crushing ratio is 1:4-6, and the maximum feed size should be controlled below 20mm.

2. Structure of the high speed fine roller crusher with double rollers for hard raw material preparation

The roller clearance of the refine roller crusher is less than or equal to 3mm, and the roller installation is supported by two hydraulic cylinder supports, which can bear the maximum load in the work.

The refine roller crusher is equipped with heavy body itself, so the steel structure is firm. The side frame is a welded rigid structure, which is machined to ensure the accuracy and shock resistance, and ensure the safe and stable operation of the equipment.

When the roller is worn, the roller ring is automatically repaired by a special grinding lathe to ensure the working quality of the equipment.

The grinding lathe is optional.

3. Structure of roller for the high speed fine roller crusher with double rollers for hard raw material preparation

In order to ensure a better neutral and support strength, the 2 rollers are supported by adjustable rolling bearing inside the high speed refine roller crusher.

The moving roller adopts pressure spring to increase force, and the crushing pressure can be adjusted according to different raw materials.

When the hard object is stuck, the spring compression will not cause damage to the roller ring.

4. Scraper for the high speed fine roller crusher with double rollers for hard raw material preparation

ll adopts cylinder loading, close to the roller, hexagram mud effect is good, and easy to repair and replace the scraper.

Each roller is equipped with an independent stepless speed reduction motor, which is used to drive the roller when the roll is repaired without starting the main motor drive. It is energy-saving and safe.

5. Techncial specifications for high speed fine roller crusher with double rollers for hard raw material preparation

| No. |

Model |

GS1080 |

| 1 |

Size of roll(diameter * width) |

1000*800mm |

| 2 |

Hardness of roll |

≥53HRC |

| 3 |

Thickness of roll surface |

≥140mm |

| 4 |

Space of roll |

<1.5 |

| 5 |

Power |

55+75(90)kw |

| 6 |

Linear speed of roll |

18.415.5m/s |

| 7 |

Production capacity |

35-50m³/h |

| 8 |

Weight |

14,800kg |

| 9 |

Dimension |

6,200*4,000*1,700mm |

6. Questions and answers

a. Which part the refine roller crusher is using for please?

Answer: The high speed refine roller crusher is using after primary roller crusher in the production line of clay brick making.

b. How long of the guartee time for the high speed roller crusher?

Answer: 1 year

c. If installation drawings is provided when the refine roller crusher is installed?

Answer: Drawings are provided when order is confirmed.

d. Training operation for the high speed roller crusher is provided or not?

Answer: Yes, it is.

e. Spares for refine roller crusher is provided or not?

Answer:Yes, it is.

f. Online inspection for the high speed roller crusher is available or not?

Answer: Yes, it is.

g. Shipment by railway, by truck and by sea are available or not?

Answer: Yes it is

7. Pictures and spares for high speed fine roller crusher with double rollers for hard raw material preparation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!