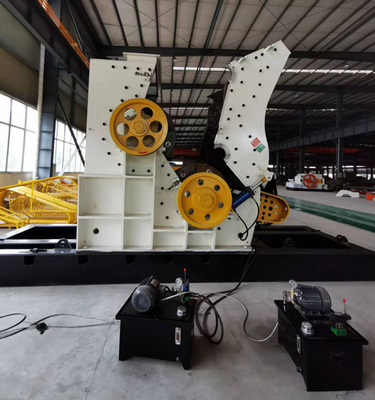

Double Roller Hammer Crusher For Processing Materials And Minerals Processing Equipment

Double-roller hammer crusher structure: two rotors are arranged horizontally, the rotor rotational speed is 100 m/s respectively, the grinding chamber width is 600 mm, two power 55KW-2-pole motors, and two impellers are installed above the rotor to feed feed roller. An adjusting guide plate device is respectively arranged above and below the adjacent areas of the rotating edges of the two rotors.

The working principle of the double-roller hammer crusher: The material enters the crushing chamber, and is evenly fed by the feeding roller with frequency conversion speed regulation, so as to ensure that each hammer of the crusher has a sufficient crushing function. The left and right rotors rotate in the same direction, and the adjacent areas of the rotating edges of the two rotors move toward each other.

1. Q: What is the functions of Dual-Rotor Hammer Crusher?

A: the dual-rotor hammer crusher is mainly used for crushing coal gangue, shale and other hard materials in clay brick making production line or other minerals industries.

2. Q: What is the main part of Dual-Rotor Hammer Crusher?

A: the key part of Dual-Rotor Hammer Crusher is hammers, lining plate, motor .

3. Q: What is the advantagers of Dual-Rotor Hammer Crusher from BBT, China?

A: The equipment is made of full-steel structure.

It is designed as upper and lower rotor, and then the material hitting distance is longer.

The casing is opened by hydraulic top, which is convenient and quick to replace the wearing parts.

The body is equipped with a sealing strip to reduce dust at maximum. .

The equipment designed without sieve plate, so that the leakage effect is good, and not blocked by the raw material.

The hammer heads and lining plate are made of high chromium alloy, which improves the service life and reduces the replacement frequency.

4. Q: Why choose BBT, China as suppliers of Dual-Rotor Hammer Crusher?

A: BBT,China has more than 15 years experience in machinery supplier for brick making industry and Minerals processing

BBT,China has own Technical R&D team, we can meet your specific requirements for machines

BBT,China has own manufacturing base with 39996m2 lands.

BBT,China has more than 15 years experience in global marketing, professional overseas services are provided.

5. Q: What is BBT,China supply?

A: Key equipment in materials processing: Hammer Crusher, Double-toothed Roller Crusher, Wet Pan Mill, Roller Mill, Extruder-mixer

Fully automatic cutting, marshalling, stacking, loading and unloading Equipment(especially for brick making factory)

Process design of directing setting, twice setting technology for clay brick making factory

Technical Parameters of Dual-Rotor Hammer Crusher for Materials Crushing and Minerals Processing Equipment. We can also supply customized equipment.

| Item |

Unit |

HC1200*2A |

HC800*2A |

| Production capacity |

t/h |

90-150 |

70-90 |

| Materials feeding size |

mm |

≤200 |

≤200 |

| Materials outlet size |

mm |

≤3 |

≤3 |

| Required power |

Kw |

160+160 |

90+90 |

| Approximate weight |

Kg |

24,000 |

10,000 |

| Total length |

mm |

5,727 |

4,234 |

| Total width |

mm |

2,510 |

1,920 |

| Total Height |

mm |

3,200 |

4,959 |

Applications of Double roller Hammer Crusher for processing materials and Minerals Processing Equipment in Brick Making Factory in China.

Our service

Welcome to contact with BBT

BBT supply following machinery and project :

1. Full automatic clay brick making machinery ( belt conveyor , box feeder, roller crusher , fine grinder. double shaft mixer , wet pan mill ,brick cutter, brick extruder ,spare parts ...)

2. Brick drying system( small brick drying room, single layer brick dryer chamber , tunnel dryer, fast rapid dryer chamber )

3. Brick kiln project ( hoffman kiln, tunnel kiln )

4. Automatic brick making system ( brick setting/stacking machine, red bricks unloading machine, brick packaging machine ...)

5. Kiln firing system ( coal / gas /oil combustion system ,control system )

6. Whole brick making project design and construction .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!