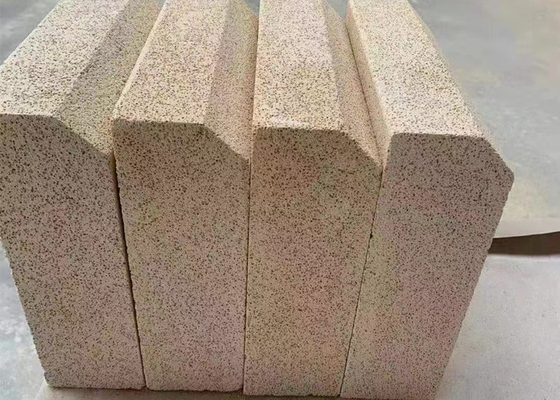

Clay Brick Tunnel Kiln Auto Brick Tunnel Kiln Project Refractory Clay Brick Tunnel Kiln Top Structure Refractory Material

General Description of Tunnel Kiln Refractory Clay Bricks Material Alkali Resistant Insulating Fire Brick:

Clay refractory bricks are refractory products with alumina content of 30~48% made of clay clinker as aggregate and refractory clay as binder.

The raw materials for making clay refractory bricks are clay minerals, and refractory clays can generally be divided into hard clay and light clay. In the refractory manufacturing process, most of the former are used as clinker after calcination; the latter, after adding water, has good plasticity and is easy to sinter, and is mostly used as a binder.

Clay minerals mainly include kaolinite (Al2O3, 2SiO2, 2H2O), dickite (same composition as kaolinite, but different lattice constants), montmorillonite (Al2O3, 4SiO2, 6H2O) and mica minerals.

Clay refractory materials are rich in raw materials, easy to process and cheap, so they are more widely used than any other refractory materials. For high temperature furnaces, hot blast furnaces, iron furnaces, ladle and casting systems and soaking furnaces, heating furnaces, non-ferrous metal melting furnaces, kilns for the silicate industry and chemical industry and chimneys and chimneys of all thermal equipment flue etc.

Main uses of clay refractory bricks: Tunnel Kiln Refractory Clay Bricks Material Alkali Resistant Insulating Fire Brick

Widely used in metallurgy, building materials, chemical industry, petroleum, machinery manufacturing, silicate, power and other industrial fields.

Applications of Refractory Bricks in Clay Brick Plant Red Clay Brick Production Line Fired Bricks in Brick Making Plant.

|

CHEMICAL COMPOSITION

|

SPEC |

TYPICAL |

| Al2O3 |

|

% |

≤35 |

32-34 |

| SiO2 |

|

% |

|

62-64 |

| Fe2O3 |

|

% |

≤1.8 |

1.6 |

| PHYSICAL PROPERTIES |

|

|

SPEC |

TYPICAL |

| Thermal Shock Resistance |

TSR - in water at 1100 °C |

cycle |

≥15 |

16 |

| Refractoriness Under Load |

RUL (0.2MPa) |

°C |

≥1310 |

1330 |

| Thermal Expansion |

TE- 1000 °C |

% |

|

0.6 |

| Cold Crushing Strength |

CCS |

MPa |

≥45 |

57 |

| Thermal Conductivity |

TC - 700士25 °C |

W/m.K |

≤1.5 |

1.5 |

| Alkali Resistance |

1100 °C*5h |

|

First grade

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!