For the technology for brick setting, there are 1 time setting or direct setting or 2 times setting by robots.

1. What is the the production line for clay brick making and how to set up a new line?

A clay brick making production line is an industrial system that transforms raw clay,

soil, mud and shale into durable building materials through a series of automated

processes. These lines are essential for the construction industry due to the consistent

demand for bricks in various civil engineering projects.

| Capacity for production line for clay brick making |

| No. |

Capacity |

What models can be produced |

Automatic degree |

Custom building |

| 1 |

100 tons/day |

Clay hollow blocks and solid bricks |

Half |

yes |

| 2 |

200 tons/day |

Clay hollow blocks and solid bricks |

Full |

yes |

| 3 |

400 tons/day |

Clay hollow blocks and solid bricks |

Full |

yes |

| 4 |

500 tons/day |

Clay hollow blocks and solid bricks |

Full |

yes |

| 5 |

600 tons/day |

Clay hollow blocks and solid bricks |

Full |

yes |

| 6 |

800 tons/day |

Clay hollow blocks and solid bricks |

Full |

yes |

| 7 |

1200 tons/day |

Clay hollow blocks and solid bricks |

Full |

yes |

How to set up a new production line for clay brick making from BBT as following:

From the beginning to the end of how to set up a production line for clay brick making are as following:

a. Raw material testing report for clay with chemical content;

b. Visiting for customer's Working site for more details;

c. Plans advising;

d. Plan and technology design;

e. Manufacturing for production line of clay brick making in BBT's workshop;

f. Clay brick making machine for production line are provided and shipped from BBT's workshop;

g. Installation and Tesing for production line of clay brick making in customer's working site;

a. Raw material testing report for clay with chemical content;

<img alt="" src=" <p> </p> <p><span style=" color:#0000ff;"="">b. Visiting for customer's Working site for more details if possible;

c. Plans advising;

d. Plan and technology design;

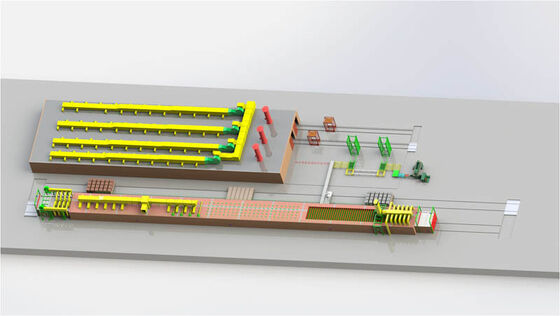

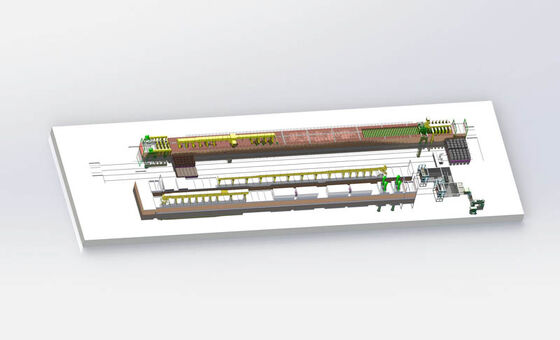

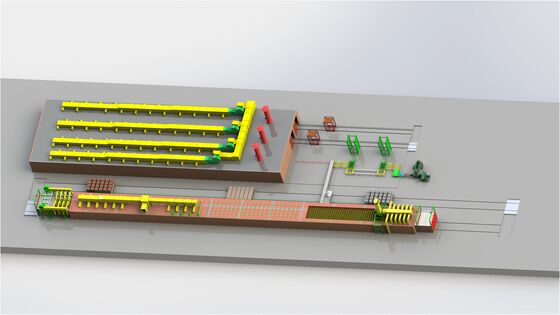

BBT provides the full design for the production line for clay brick making, installation drawings,

assembly drawings and foundamental drawings all are included:

e. Manufacturing for production line of clay brick making in BBT's workshop;

f. Clay brick making machine for production line are provided and shipped from BBT's workshop;

g. Installation and Tesing for production line of clay brick making in customer's working site;

2. Training operation for customer's workers after installation and trial running, which will be provided

by engineers from BBT:

3. Robot setting for kiln cart and unloading fired bricks from kiln cart

Famous brand of robots, such as Fanuc robot and kuca robot with grispers for clay brick setting to kiln cart

and unloading kiln cart after brick fired can be provided;

4. Single layer dryer for clay hollow blocks and solid bricks by tunnel dryer or chamber dryer,

drawings and equipment are designed and manufactured by BBT, cone fans will be installed for

drying better;

5. Automatic loading and unloading systems, and progromming systems for clay hollow blocks

and solid bricks:

6. BBT's factory and workshop for production line of clay brick making as following, BBT is

the manufacturer, factory and designer for new production line setting setting and old line modifications:

How many tons/day for the clay production line can be set up?

How many tons/day for the clay production line can be set up?

Answer: 100 tons/day to 1200 tons/day production line is available, working time for raw material

preparation and molding is 1 shift or 2 shifts(1shaft=8 hours); working time for dryer and kiln is 24 hours;

- What kind of clay bricks can be produced by the clay production line?

Answer: a. Clay solid bricks; b. clay hollow blocks; c. clay facing bricks;

All bricks can be custom building according to requirement.

- What is the automatic degree for the clay production line?

Answer: a. Fully automatic production line;

b. Semi-automatic production line;

c.Manual production line

4. What is the equipment included in the production line for clay brick making?

Answer:

- Equipment for raw material crushing;

- Equipment for raw material preparation;

- Equipment for aging House/room;

- Equipment for brick molding;

- All belt Conveyors for equipment connection;

- Equipment for brick cutting systems;

- Equipment for programming, automatic loading & dried bricks unloading system;

- Equipment for dryer and fans;

- Equipment for tunnel kiln and fans;

- Running equipment of kiln carts;

- Equipment for automatic kiln cart unloading and fired bricks automatic packing section;

5. What is the requirement for setting up a new brick factory with a production line for clay brick making?

Answer: For setting up a new brick plant, some documents and

- Raw material analysis report of clays with chemical contents, drying time, firing time and conclusions;

- Land size with length and width needs to be provided;

- Models, brick sizes and weights need to be provided

- Capacity for how many tons of bricks will be produced needs to be provided

6. What fuel can fire the bricks?

Answer:

Natural Gas

Fuel-Oil

PetCoke

Coal

Biomass

BioGas

Others

- What about the special requirement about setting up a brick plant?

Answers: Custom building is accepted.

- How about BBT company?

BBT is referred to brick, block and tile; BBT is the factory and manufacturer with R&D department

for clay brick making machine and production line.

- What is the quality standard for brick making machine and production line from BBT?

Answers: As a manufacture with its own designing teams, BBT’s equipment is high quality with

CE certification, SGS inspection before shipment is also accepted;

- What about installation, assembly and training for operation from BBT?

Answer:

Engineers from BBT will be sent to the working site for guiding installation, assembly and training

operation after all equipment arrived inside the factory.

- What about the after-sale service for the production line pls?

Answer: After trial running of the line is finished, engineers can stay in the factory for working for

1- 2 years; 7x24 hours online service is also available;

Contact for more details for production line of clay brick making

XI'AN BBT CLAY TECHNOLOGIES CO.,LTD

Noda Pan

General manager

nodapan@claybbt.com

WA/wechat+86 177 9142 2086

www. claybbt.com

www.claybricksmakingmachines.com

www.claybbt.ru

YouTube: https://www.youtube.com/@BBTChina

Facebook: https://www.facebook.com/bbt15/

Linkedin:https://www.linkedin.com/in/noda-pan-56a524236/

What'sApp talking online Wechat talking online

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!